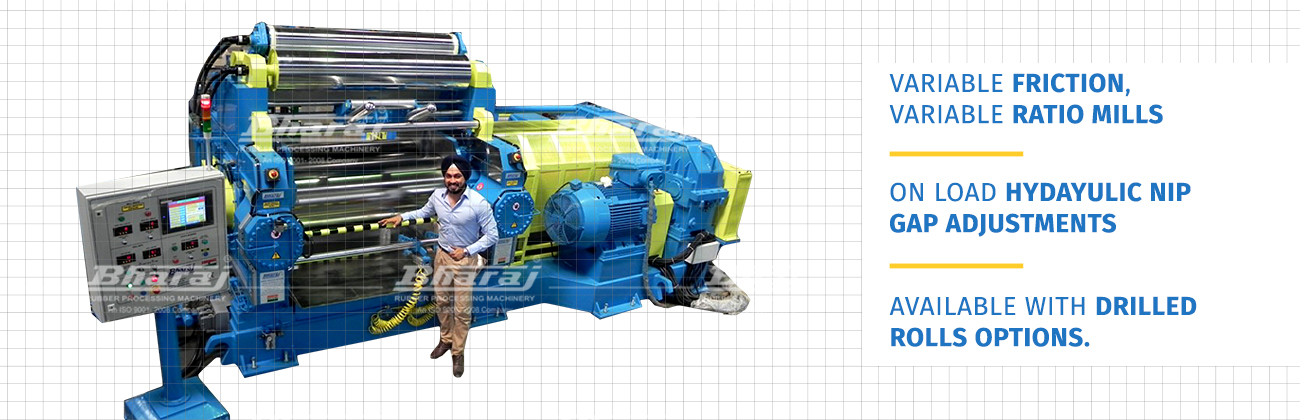

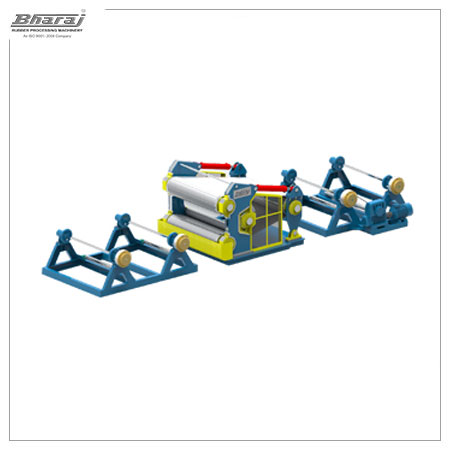

- Variable friction & variable ratio machine with hydraulic nip gap adjustment.

- Hydraulic nip gap adjustment equipped with peripherally drilled rolls variable friction & variable ratio.

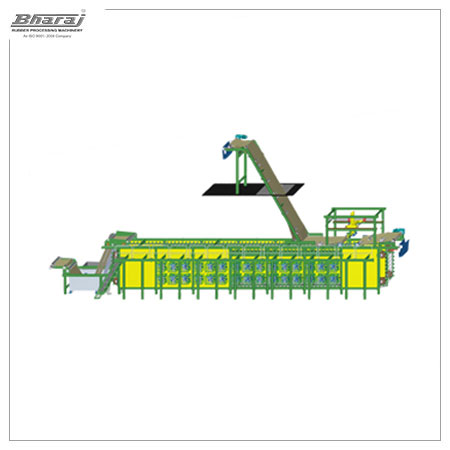

- Fully automatic rubber mixing mill. Power saving machines, helps by saving 20 to 30% electricity.