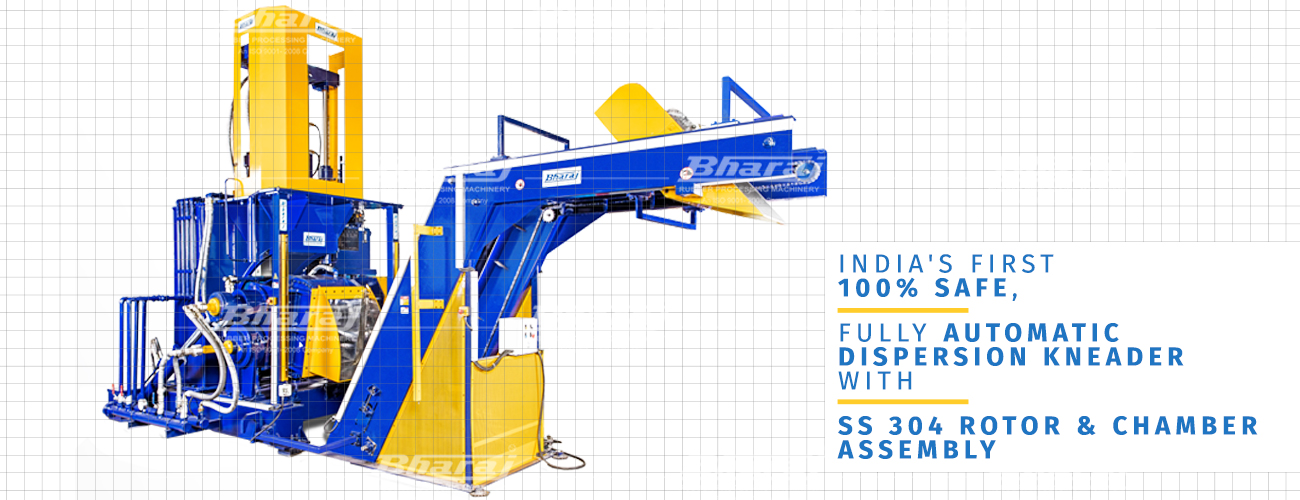

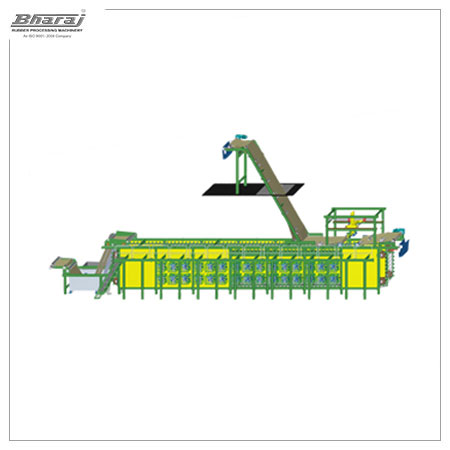

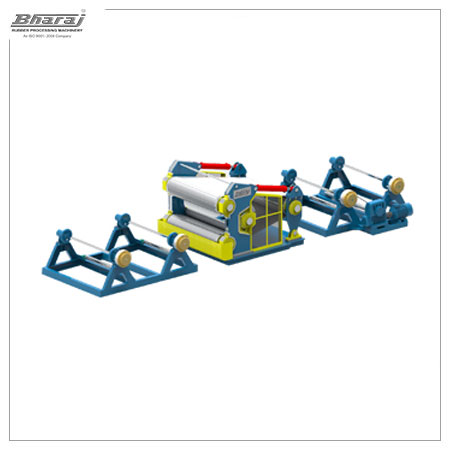

Bharaj Super Mix Kneader is most Suitable For Hoses Compound, Silicon Rubber, Belts, Gaskets, Sponge, Soles, Sandals, Automobile, Mechanical Goods & Master Batches, E.V.A. Phenol, Polythene, Thermoplastic Resins & Allied Rubber Industries.

Equipped With Hydraulic Tilting System Practically Zero Maintenance in the Tilting System to Other Machines (Optional Feature).